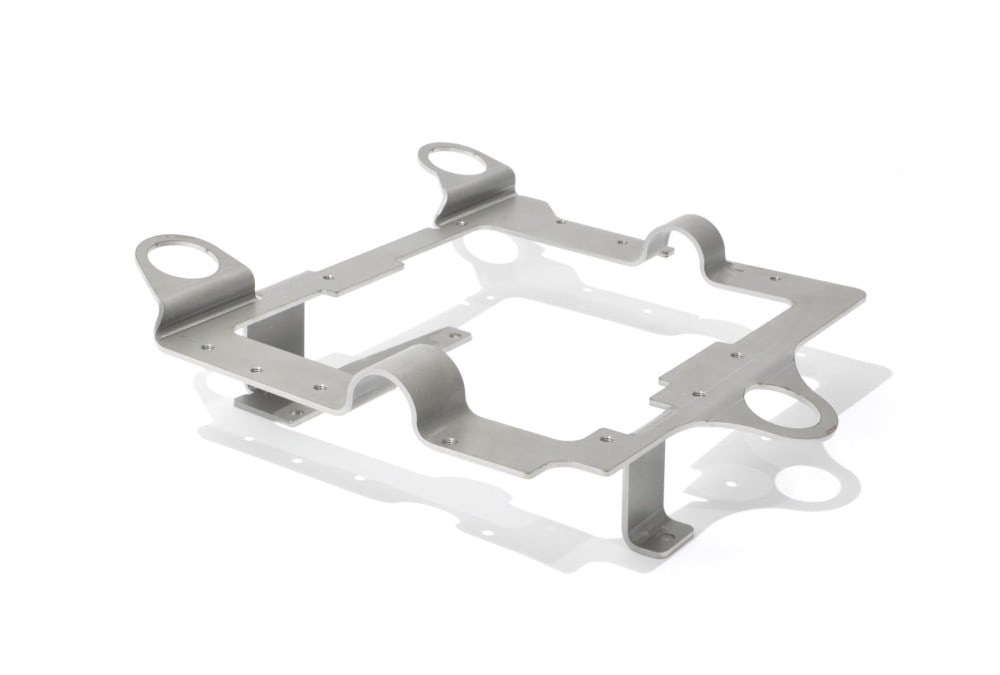

Steel parts fabrications

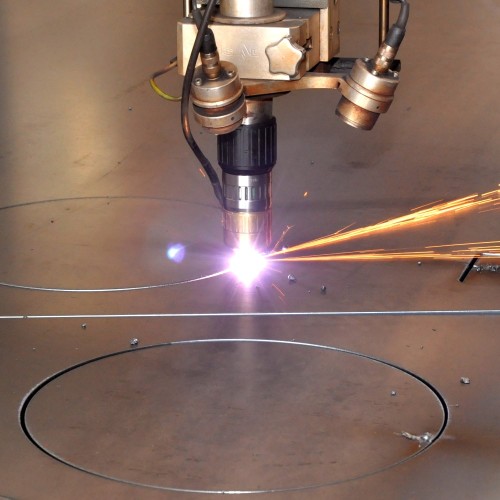

Laser cutting of sheets

We are capable of cutting any shapes with laser cutters out of metal sheets with dimensions of 1500 x 3000 from following materials:

✔ Carbon steel – up to 20 mm

✔ Stainless and acid resistant steel– up to 15 mm

Cutting components with a laser beam in combination with a modern control technology allows to achieve:

✔ High accuracy of cut out details– 0,01 mm

✔ 100% repeatability of cut components

✔ High quality of edges without application of additional processing

✔ Any designed shape

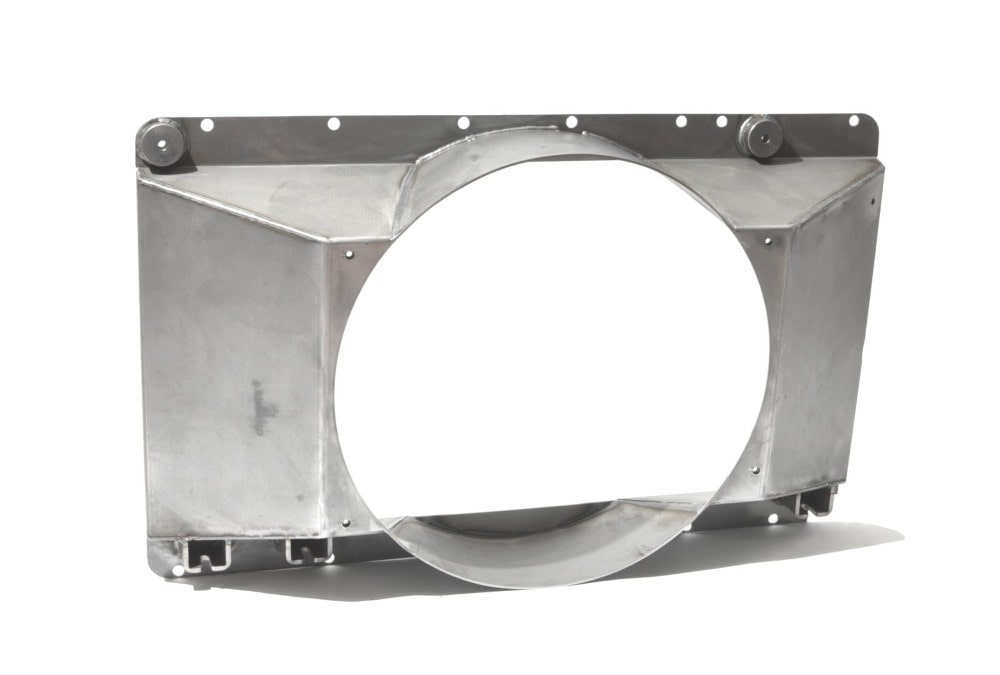

Sheet bending

Our CNC press breaks allow to achieve high accuracy and repeatability of the process of brake bending of sheets with following parameters:

✔ Maximum length of bending 3050 mm

✔ Maximum pressure up to 220 ton

✔ Segmental punches with end components– to bend partly closed components

✔ Thickness of bent materials from 0,5 to 25,0 mm

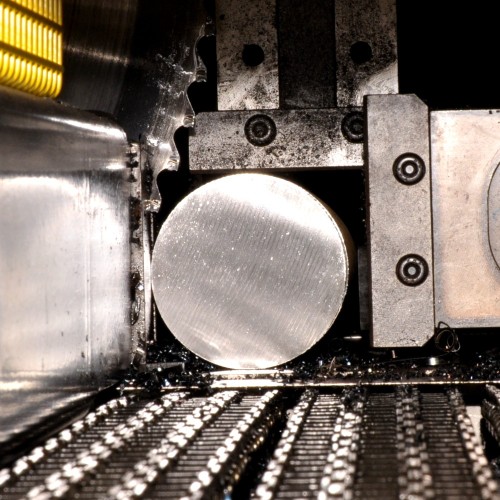

Cutting of metallurgical materials

Modern fast circular saw for cutting of metallurgical materials such as pipes, rods, profiles.

✔ Fast & repeatable cut with precision up to 0,1 mm

✔ Dimensions of the cut: diameter from 30 to 155 mm, length up to 1500 mm

✔ Cutting at angle of 90 degrees

Automatic band saw for cutting of metallurgical materials & profiles

✔ Capability to cut at angle between 60 and 90 degrees

Bending of pipes and profiles

Bender with CNC control for bending of pipes, profiles and rods.

✔ Bending of pipes and profiles with diameter of 80 mm

✔ Bending of full rods with diameter up to 40 mm

✔ Maximum angle of bending 190 degrees

✔ Maximum length of the material 4500 mm

✔ Option of interception with capability for performing a simulation of bending

Manual welding & spot-welding

We offer technologies of joining steel through the process of welding and spot-welding. We work as modern invert spot-welding machines with power of 180 kVA equipped with automatic feeders of nuts. We perform manual welding with MAG, MIG and TIG methods.

We offer welding of:

✔ Carbon steel

✔ Stainless steel

✔ Brass

Quality control of manufactured products

Internal examination of welded joints

✔ Conducting visual examination (VT) compliant to EN ISO 5817

✔ Conducting internal metallographic examinations compliant to EN 1321

✔ Tests of breaking and examination of breakthroughs compliant to EN 1320

3D Optical measurement system

✔ Measurement of GD&T characteristic

✔ Comparison with CAD data

✔ Measurement of large products

(8 meter measurement range without moving the measurement system)

✔ Precision for 1 m3 – 0.02 mm

Additionally there are possibility of measurements of hardness for materials.

Cooperation with Tool Department

Production department of metal components cooperates with tool department in the scope of manufacture of specialist production equipment: punching tools, bending dies and welding and assembly equipment.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)